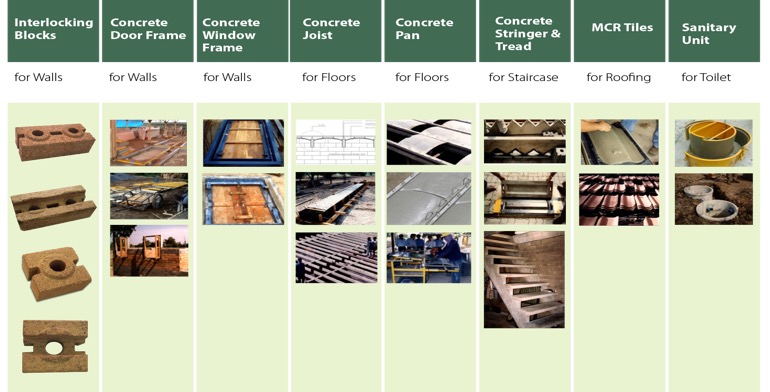

Components

- Interlocking Bricks – for Walls

- Concrete Door Frame – for Walls

- Concrete Window Frame – for Walls

- Concrete Joist – for Floors

- Concrete Pans – for Floors

- Concrete Stringer – for Staircase

- Concrete Treads – for Staircase

- MCR Tiles – for Roofing

The components of Habitech Building Systems are:

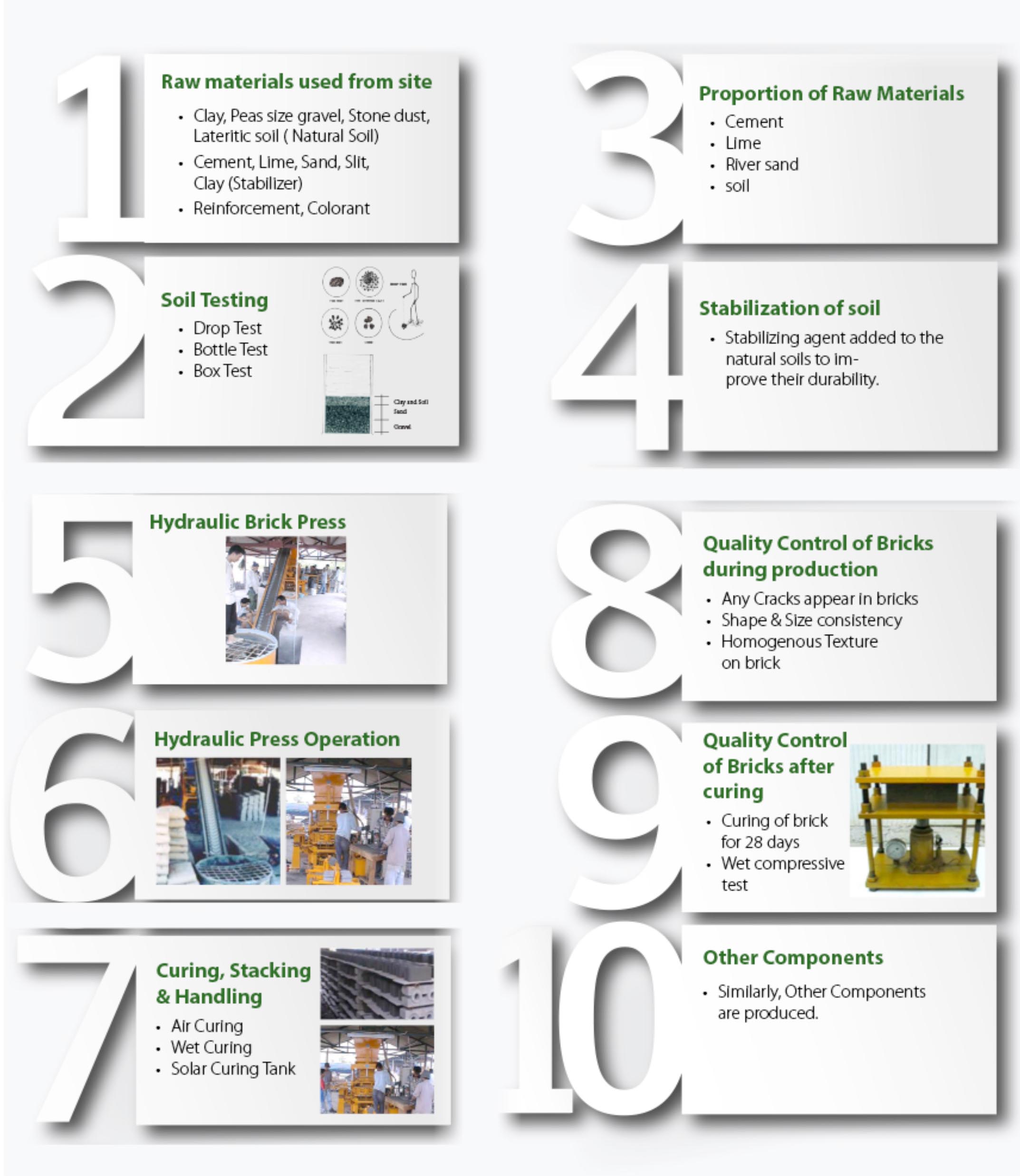

1. Concrete Joist

- Assembled in floors or roofs

- Prefabricated in steel beds

- Maximum length-7.1m with maximum clear span of 5.10m

- Load bearing capcity-2000kg/m2

2. Micro Concrete Pans

- Used as form work between the joist to cast concrete floors or roofs and forms short arches

- Produced in vibrating tables with 1cm thickness

- Pans stay in place after concrete is cast and can be simply painted underneath as a finished ceiling

3. Concrete Doors and Window Frames

- Soil cement concrete frame can be cast to form complete pre-assembled units with panels and hardware already in place

- Frames are grouted to interlocking bricks

4. Sill and Lintel

- 2-levels of U-channel interlocking bricks with horizontal reinforcement

5. Plinth

- 2 layer of DPC

- 2 layers of U-channel interlocking bricks with horizontal reinforcement

6. MCR Roofing Tiles

- Tiles are produced using workstations and ABS plastic molds

- Thickness-8 to 10mm with corresponding weight 2.2 and 2.8kg with bearing capacity of 50 and 80kg

7. Interlocking Bricks

- Soil cement or concrete bricks for wall are laid dry (no mortar) as the positive and negative elements automatically align the bricks

- Water cannot penetrate the joints as grouts are filled with cement

8. Staircase

- Free standing reinforced concrete staircase is used

- Prefabricated using steel molds

- Treads can be open or close

9. Foundation

- Adjustable steel molds to cast foundation and ground floor, allow for quick and easy construction and level floors without the necessity of staking the foundation of the building